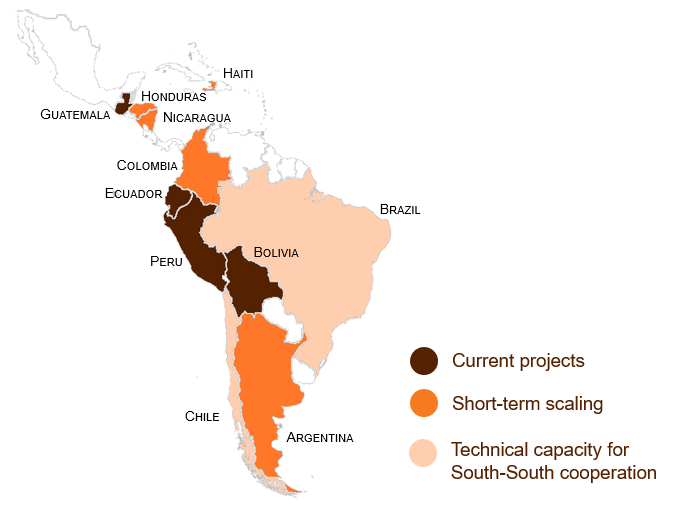

Latin America and the Caribbean

CONTEXT

In the countries of Latin America and the Caribbean (LAC), we can see the effects of a rapidly changing food system that drives land use conversion, focuses on food export, and ignores the unparalleled agrobiodiversity of the region. Consider that, in the Latin America and Caribbean region:

- There are approximately 187 million people face food insecurity, and nearly 43 million go hungry.

- The region suffers double burden of malnutrition, for each hungry person, there are six people considered obese or overweight.

- In Guatemala, almost 50% of children under five are malnourished. In the Peruvian highlands, nearly 44% of children between 6-36 months are anemic.

These are only a few relevant statistics within a larger story of endemic food and nutrition insecurity that has crippled the region for the past century. When you add the rising impacts of climate change on weather and the incidence of natural disaster, the outlook is even more discouraging.

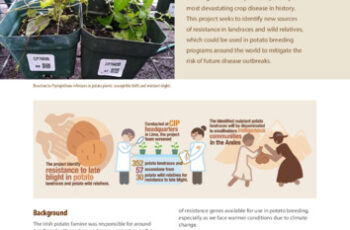

Latin America is the largest net exporter of foods, supported by the region’s lush biodiversity. Indeed, the region comprises six of the world’s ten most biodiverse countries. However, the recent focus on food export and processed foods have neglected local resources and traditional food system practices. Land use conversion—the conversion of natural ecosystems to agriculture land—is three times the global rate and 13 of 107 known potato wild relatives are currently at risk for extinction.

But details like these need not define the region’s future. Pivoting the region to focus on its biodiversity could usher in many needed improvements in food and nutrition security while also sustainably restoring food systems to promote inclusive growth for smallholder farmers and other vulnerable groups.

OUR APPROACH

The International Potato Center (CIP) investigates the critical interplay between food systems and the natural environment, using a range of participatory methodologies (especially for women and young people) to monitor, restore and create value from agrobiodiversity as the basis for inclusive market systems and healthier diets.

Partnerships play a fundamental role in our success, particularly with the private sector, as this engenders innovation, efficiency and self-sufficiency for smallholder farmers. Furthermore, working with CIP opens doors for private sector actors looking to create inputs that support smallholder farmers.

Our technologies, tools and innovations have a high rate of adoption (e.g., 31% of all potato varieties in Peru were developed using CIP germplasm), as we work directly with local stakeholders to ensure products meet their needs while protecting the environment. We collaborate with a range of partners, including farmers and their organizations, academia, the private sector, civil society and government agencies.

VISION

Our vision is a Latin America and the Caribbean region that contributes to a planet where the food we produce is healthy, nutritious, enhances environmental sustainability, and benefits the communities working so hard to preserve it.

OBJECTIVES

Our high quality and transdisciplinary science-based solutions seek to:

- Promote in situ conservation and sustainable use of agrobiodiversity.

- Adapt and scale innovative and participatory climate action.

- Facilitate the transition towards healthy diets for all.

Designing and implementing collaborative, disruptive and impactful interventions that consistently provide science-based solutions to achieve sustainable systemic change in agri-food systems as the foundation for impact at scale require:

We actively participate in and encourage dynamic, strategic partnerships with key stakeholders from different sectors and communities, including but not limited to food, health, education, conservation and extractive industries.

For in-depth action research and co-innovation with real relevance for farmers, consumers, development actors, policymakers and other actors, we believe it is essential to commit to key research sites. Ideally these sites are suited to integrate the criteria for being food sheds, agrobiodiversity hotspots, and climate action co-laboratories.

Delivering impact starts with research and publishing in high impact journals, staying embedded in current research-for-development cycles and trends, translating science to practice and vice versa, and offering a portfolio diverse outputs ranging from tools, methods, evidence to technologies. Through our research we will build data infrastructure (open access) for intelligence and time-line comparisons, and we will embed knowledge management into translational science concerning complex systems. Our research will provide solid data about our contributions to the 2030 Agenda (the Sustainable Development Goals).

Climate change and food systems entail significant complex ideas and dynamics. The knowledge generated from our research will be translated for broader uptake, targeted to key audiences and made actionable for policy and development actors.

ACHIEVEMENTS

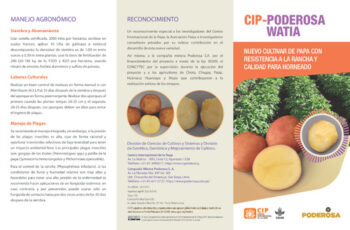

- Integrated conservation of agrobiodiversity on-farm and ex-situ, and active use of this diversity to the develop new varieties. More than forty potato and sweetpotato varieties have been released in the Latin America and Caribbean region alone. The most important potato varieties in Peru and Costa Rica were bred using CIP germplasm.

- Inclusive value chain linkages to reposition native potato biodiversity in urban markets. Thousands of smallholders now have access to increased income, more stable market linkages and several new products on the market.

- A portfolio of participatory methods and tools developed in LAC and globally deployed with success: Participatory market chain approaches, farmer fields schools, and participatory varietal selection.

PROJECTS

Andean Initiative

- Location: Ecuador

- Implementation period: January 2020 – March 2022

- Total Investment: EUR 475,000

- Funding partners: Agencia Española de Cooperación Internacional para el Desarrollo (AECID)

- Implementing partners: Inter-American Institute for Cooperation on Agriculture (IICA), National Institute of Agricultural Research of Ecuador (INIAP)

- Location: Peru

- Implementation period: March 2019 – September 2021

- Total Investment: CAD 500,000

- Funding partners: International Development Research Centre (IDCR)

- Implementing partners: Instituto de Investigación Nutricional Peru (IIN), Asociación Pataz

- Location: Bolivia, Ecuador, Peru.

- Implementation period: June 2019–21

- Total Investment: USD 1.39 million

- Funding partners: European Union, Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ)

- Implementing partners: IICA

- Location: Bolivia, Ecuador, Peru.

- Implementation period: February 2019–August 2020

- Total Investment: EUR 350,000

- Funding partners: AECID

- Implementing partners: PROINPA Foundation Bolivia, INIAP, Centro de Desarrollo Integral de Comunidades (CEDINCO)

- Location: Peru

- Implementation period: January 2020–December 2020

- Total Investment: USD 200,000

- Funding partners: CGIAR Trust Fund donors

- Implementing partners: Servicio Nacional Forestal y de Fauna Silvestre (SERFOR)

- Location: Bolivia, Ecuador, Peru

- Implementation period: December 2015–18

- Total Investment: USD 1,400,000

- Funding partners: International Fund for Agricultural Development (IFAD)

- Implementing partners: PROINPA Foundation, Ministerio de Agricultura y Riego Peru, Ministerio de Agricultura Bolivia, Ministerio de Agricultura y Ganadería Ecuador, INIAP, Oficina para Estudios del Agro (OFIAGRO), TRIAS Foundation, Asociación para el Desarrollo Sostenible del Perú (ADERS).

- Location: Bolivia, Peru

- Implementation period: December 2015–17

- Total Investment: USD 552,000

- Funding partners: European Union

- Implementing partners: The Andean Community (CAN), CARE Peru, Alternativas Agropecuarias.

- Location: Bolivia, Ecuador, Peru

- Implementation period: March 2011–June 2014

- Total Investment: USD 6,187,850

- Funding partners: International Fund for Agricultural Development (IFAD), European Union

- Implementing partners: World Vision, PROINPA Foundation, INIAP, Asociación para el Desarrollo Sostenible del Peru (ADERS), Prisma, IIN.

- Location: Peru

- Implementation period: July 2001–August 2011

- Total Investment: USD 2,519,345

- Funding partners: Swiss Agency for Development and Cooperation (SDC)

- Implementing partners: Asociación para el Desarrollo Sostenible del Peru (ADERS), Coordinadora de Activistas del Patrimonio Ambiental y Cultural (CAPAC), Fomento de la Vida (FOVIDA), CARE, Caritas, National Institute of Agrarian Innovation (INIA), Ministry of Agriculture of Peru, Exports and Tourism Promotion Board of Peru (PROMPERU), EMSMSA, Food and Agriculture Organization of the United Nations (FAO), PepsiCo, Wong Supermarkets.

- Location: Bolivia, Ecuador, Peru.

- Implementation period: July 1998 – June 2011

- Total Investment: CHF 8,320,000

- Funding partners: SDC

- Implementing partners: PROINPA Foundation, INIAP, INCOPA project.

Central America

- Location: El Salvador, Guatemala, Nicaragua

- Implementation period: 2020–23

- Total Investment: USD 575,000

- Funding partners: Korea International Cooperation Agency (KOICA).

- Implementing partners: World Food Program (WFP).

CONTACTS

Ginya Truitt Nakata

Regional Director, Latin America & the Caribbean

.

Horacio Rodríguez Vázquez

Senior Manager, Operations & Impact at Scale

.

Stef de Haan

Senior Scientist Andean Food Systems & Lead of the Andean Initiative

Claudio Velasco Mac Lean

Central America Coordinator