Duplex Stainless Plate

Sandmeyer Steel Company maintains an extensive inventory of LDX 2101 stainless steel plate in thicknesses from 3/16" (4.8mm) through 2.0" (50.8mm). The alloy is a low nickel, lean duplex stainless steel possessing both superior strength and chloride stress-corrosion cracking resistance when compared to 300 series stainless steels.

Available thicknesses for Alloy LDX 2101®:

| 3/16" | 1/4" | 5/16" | 3/8" | 1/2" | 5/8" | 3/4" | |

|---|---|---|---|---|---|---|---|

| 4.8mm | 6.3mm | 7.9mm | 9.5mm | 12.7mm | 15.9mm | 19mm | |

| 7/8" | 1" | 1 1/4" | 1 1/2" | 1 3/4" | 2" | ||

| 22.2mm | 25.4mm | 31.8mm | 38.1mm | 44.5mm | 50.8mm | ||

LDX 2101 (UNS S32101) is a 21.5% chromium, 5% manganese, 1.5% nickel, 0.45% molybdenum lean duplex stainless steel with corrosion resistance superior to 304L and comparable to 316L. LDX 2101 possesses both superior strength and greater chloride stress-corrosion cracking resistance than conventional 300 series stainless steels.

The enhanced mechanical strength of LDX 2101 enables it to be used in thinner cross-sections which can provide significant cost savings to the end user. LDX 2101 was designed to be a low nickel general purpose substitute for 304 and 304L.

Specification Sheet Overview

for Alloy LDX 2101® (UNS S32101)

EN 1.4162:

General Properties

LDX 2101 is a low-nickel, nitrogen enhanced lean duplex stainless steel developed for general-purpose use. The austenitic-ferritic (duplex) structure of the alloy is balanced to approximately equal amounts of ferrite and austenite in the solution-annealed condition.

The high chromium and nitrogen content of LDX 2101, combined with an addition of molybdenum, provide very good resistance to localized and uniform corrosion. The duplex microstructure contributes to the alloys high strength and resistance to chloride stress-corrosion cracking. LDX 2101 possesses both superior strength and greater chloride stress-corrosion cracking resistance than conventional 300 series stainless steels.

The corrosion resistance of LDX 2101 is generally good making it suitable for use in a wide variety of applications. In most environments, it is superior to 304L stainless steel and comparable to the molybdenum containing 316L stainless steel.

The enhanced mechanical strength of LDX 2101 is far superior to conventional 300 series stainless steels enabling it to be used in thinner cross-sections which can provide significant cost savings to the end user.

LDX 2101 exhibits good abrasion and erosion resistance and can be fabricated using standard shop practices developed for duplex stainless steels.

Applications

- Air Pollution Control

- External absorber and outlet duct reinforcements

- Biofuels

- Biodiesel and Ethanol plants and tanks

- Chemical Process Equipment

- Pressure vessels, heat exchangers, tanks, piping systems and tankers

- Food and Beverage Process Equipment

- Palm oil and wine storage tanks

- Infrastructure

- Bridges, flood gates, sluice gates

- Pulp and Paper

- Hydrogen peroxide bleaching reactors, white liquor storage tanks, digesters, washers, paper machine parts

- Seawater Treatment

- Desalination system chambers and evaporators

- Water and Wastewater Treatment

Standards

ASTM..................A 240ASME..................SA 240

Chemical Analysis

Typical Values (Weight %)

| Chromium | 21.0 min. - 22.0 max. | Nickel | 1.35 min. - 1.70 max. |

| Manganese | 4.00 min. - 6.00 max. | Molybdenum | 0.10 min. - 0.80 max. |

| Nitrogen | 0.20 min. - 0.25 max. | Chromium | 0.040 max. |

| Silicon | 1.00 max. | Phosphorus | 0.040 max. |

| Copper | 0.10 min. - 0.80 max. | Nitrogen | 0.030 max. |

| Iron | Balance* |

* Alloy predominates remaining composition. Other elements may be present only in minimal quantities.

Physical Properties

| Temperature, °F | |||||

|---|---|---|---|---|---|

| 68 | 200 | 400 | 600 | ||

| Density | lb/in3 | 0.28 | |||

| Modules of Elasticity | x 10sup>6 psi | 29 | 28 | 27 | 26 |

| Poissons Ratio | 0.3 | ||||

| Linear Expansion | x 10-6 in/in/°F | — | 7.2 | 7.5 | 7.5 |

| Thermal Conductivity | Btu/ft/h °F | 8.7 | 9.3 | 9.8 | 10.4 |

| Thermal Capacity | J/kg °F | 500 | 530 | 560 | 590 |

| Electric Resistivity | micro-ohms•meter | 0.80 | 0.85 | 0.90 | 1.00 |

Mechanical Properties

| Minimum values (.625" Plate) |

Typical values (.625" Plate) |

||

|---|---|---|---|

| 0.2% Offset Yield Strength | ksi | 65 | 69 |

| Tensile Strength | ksi | 94 | 101 |

| Elongation | % | 30 | 38 |

| Hardness (Brinell) | HB | 290 (max) | 225 |

Design Stress Allowance

One of the advantages of nitrogen-enriched duplex stainless steels is their higher strength levels in comparison to conventional austenitic stainless steels. This allows for construction of units with thinner cross-sections. This weight savings can dramatically reduce the material and fabrication cost of a vessel.

ASME Boiler & Pressure Vessel Code, Section VIII, Division 1, Allowable Stress Values, ksi

| Alloy | 200 °F | 300 °F | 400 °F | 500 °F | 600 °F |

|---|---|---|---|---|---|

| LDX 2101 | 26.9 | 25.6 | 24.7 | 24.7 | 24.7 |

| 304L | 20.0 | 18.9 | 18.3 | 17.5 | 16.6 |

| 316L | 20.0 | 20.0 | 19.3 | 18.0 | 17.0 |

| 2205 | 25.7 | 24.8 | 23.9 | 23.3 | 23.1 |

| 2304 | 24.0 | 22.5 | 21.7 | 21.3 | 21.0 |

Corrosion Properties

The 300 series stainless steels are used extensively in numerous process industries due to their overall general corrosion resistance. The corrosion resistance of LDX 2101 is generally better than 304L and comparable to 316L making it suitable for use in a wide variety of industries and applications.

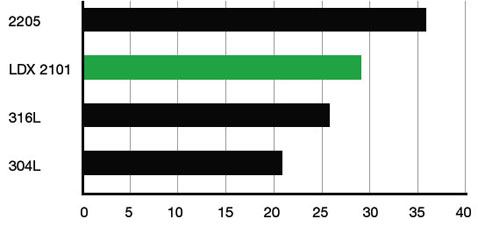

Chloride Pitting Resistance

The pitting resistance of an austenitic stainless steel can be related directly to alloy composition, where chromium, molybdenum and nitrogen are a weight %. The Pitting Resistance Equivalent Number (PREN) uses the following formula to measure an alloy's relative pitting resistance - the higher the number, the better the pitting resistance.

PREN = %Cr + 3.3Mo + 30N

The following chart compares the PREN for LDX 2101 with other common stainless steels.

Pitting Resistance Equivalent PREN = %Cr + 3.3Mo + 30N

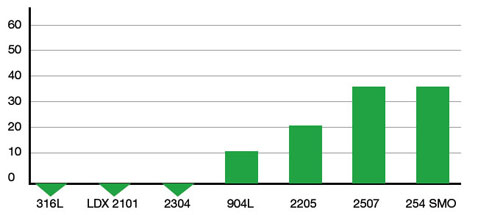

Crevice Corrosion Resistance

The Critical Crevice Corrosion Temperature (CCCT) test is often used to compare the crevice corrosion resistance of various alloys.

Typical critical crevice corrosion temperature according to ASTM G48 Method F

Stress-Corrosion Cracking Resistance

Chloride stress-corrosion cracking (SCC) is one of the most serious forms of localized corrosion. Higher temperatures and reduced pH will increase the probability of SCC. The onset of SCC is one of the most common reasons for stainless equipment failure. Because of its duplex structure LDX 2101 offers excellent resistance to SCC.

Results from U-bend testing in a 40% CaCl2 boiling solution (100ºC) for 500 hours

| Longitudinal/Transverse | |

|---|---|

| LDX 2101 | No SSC |

| 304L | SSC Cracking (<150hrs) |

General Corrosion

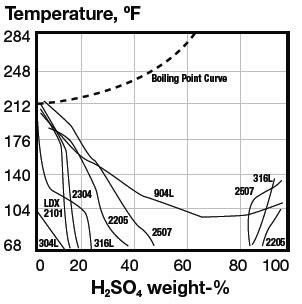

General corrosion is characterized as a uniform attack on a surface in contact with a corrosive medium. The resistance to uniform corrosion in sulfuric acid is shown below. LDX 2101 is superior to 304L and in some cases comparable to 316L.

Isocorosion curves, 0.1 mm/year, in sulfuric acid

LDX 2101 and 254 SMO are registered trademarks of Outokumpu Stainless, Inc.

NOTE: The information and data in this product data sheet are accurate to the best of our knowledge and belief, but are intended for informational purposes only, and may be revised at any time without notice. Applications suggested for the materials are described only to help readers make their own evaluations and decisions, and are neither guarantees nor to be construed as express or implied warranties of suitability for these or other applications. Stainless Steel, Nickel Alloy and Titanium products are classified as sheet if the thickness of the metals is less than 3/16” (4.7mm). If the thickness of the metal is 3/16” (4.7mm) or more, then it is considered a plate.