Placa de Aleación de Níquel

La Aleación 625 (UNS N06625) es una superaleación austenítica a base de níquel que posee excelente resistencia a la oxidación y corrosión dentro de un amplio rango de condiciones corrosivas, incluyendo ambientes de motores de jet, así como en muchas aplicaciones aeroespaciales y de procesos químicos. La aleación tiene una resistencia mecánica y tenacidad sobresalientes a temperaturas que van desde niveles criogénicos hasta los 2000° F (1093° C). La Aleación 625 tiene también una excepcional resistencia a la fatiga.

| 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" | |

|---|---|---|---|---|---|---|---|

| 4.8mm | 6.3mm | 9.5mm | 12.7mm | 15.9mm | 19mm | 25.4mm | |

| 1 1/4" | 1 1/2" | 1 3/4" | 2" | 2 1/2" | 3" | ||

| 31.8mm | 38.1mm | 44.5mm | 50.8mm | 63.5mm | 76.2mm | ||

An Austenitic Nickel-Chromium-Molybdenum-Niobium Alloy with Outstanding Corrosion Resistance and High Strength from Cryogenic Temperatures to 1800°F (982°C)

Specification Sheet Overview

for Alloy 625 (UNS N06625)

W. Nr. 2.48161:

General Properties

Alloy 625 is an austenitic nickel-chromium-molybdenum-niobium alloy possessing a rare combination of outstanding corrosion resistance coupled with high strength from cryogenic temperatures to 1800°F (982°C).

The strength of Alloy 625 is derived from the solid-solution hardening of the nickel-chromium matrix by the presence of molybdenum and niobium. Therefore, precipitation-hardening treatments are not required.

The chemical composition of Alloy 625 is also responsible for its outstanding corrosion resistance in a variety of severe operating environments along with resistance to oxidation and carburization in high temperature service. The alloy is resistant to pitting, crevice corrosion, impingement corrosion, intergranular attack and is almost immune to chloride stress corrosion cracking.

Alloy 625 can be easily welded and processed by standard shop fabrication practices.

Applications

- Aerospace Components – bellows and expansion joints, ducting systems, jet engine exhaust systems, engine thrust-reversers, turbine shroud rings

- Air Pollution Control – chimney liners, dampers, flue gas desulfurization (FGD) components

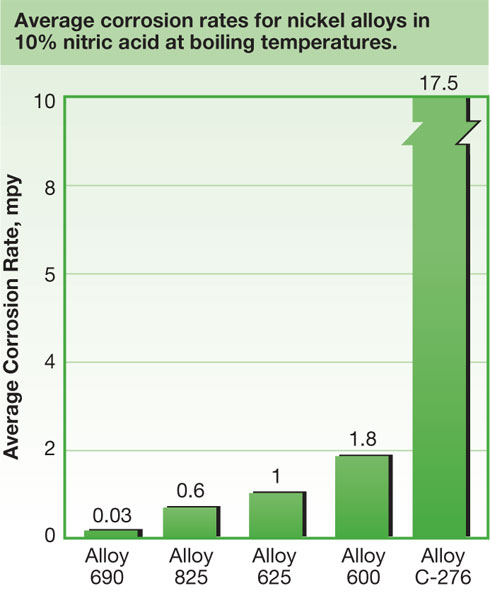

- Chemical Processing – equipment handling both oxidizing and reducing acids, super-phosphoric acid production

- Marine Service – steam line bellows, Navy ship exhaust systems, submarine auxiliary propulsion systems

- Nuclear Industry – reactor core and control rod components, waste reprocessing equipment

- Offshore Oil and Gas Production – waste flare gas stacks, piping systems, riser sheathing, sour gas piping and tubing

- Petroleum Refining – waste flare gas stacks

- Waste Treatment – waste incineration components

Standards

ASTM..................B 443ASME..................SB 443

AMS ...................5599

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | 58.0 min. | Silicon | 0.50 |

| Chromium | 20.0 min.-23.0 max. | Phosphorus | 0.015 |

| Molybdenum | 8.0 min.-10.0 max. | Sulfur | 0.015 |

| Iron | 5.0 | Aluminum | 0.40 |

| Niobium (plus Tantalum) | 3.15 min.-4.15 max. | Titanium | 0.40 |

| Carbon | 0.10 | Cobalt (if determined) | 1.0 |

| Manganese | 0.50 |

Physical Properties

Density

0.305 lbs/in38.44 g/cm3

Specific Heat

0.102 BTU/lb-°F (32-212°F)427 J/kg-°K (0-100°C)

Modulus of Elasticity

30.1 x 106 psi207.5 GPa

Thermal Conductivity 200°F (100°C)

75 BTU/hr/ft2/ft/°F10.8 W/m-°K

Melting Range

2350 – 2460°F1290 – 1350°C

Electrical Resistivity

50.8 Microhm-in at 70°C128.9 Microhm-cm at 210°C

| Mean Coefficient of Thermal Expansion Temperature Range |

|||

|---|---|---|---|

| °F | °C | in/in/°F | cm/cm°C |

| 200 | 93 | 7.1 x 10-6 | 12.8 x 10-6 |

| 400 | 204 | 7.3 x 10-6 | 13.1 x 10-6 |

| 600 | 316 | 7.4 x 10-6 | 13.3 x 10-6 |

| 800 | 427 | 7.6 x 10-6 | 13.7 x 10-6 |

| 1000 | 538 | 7.8 x 10-6 | 14.0 x 10-6 |

| 1200 | 649 | 8.2 x 10-6 | 14.8 x 10-6 |

| 1400 | 760 | 8.5 x 10-6 | 15.3 x 10-6 |

| 1600 | 871 | 8.8 x 10-6 | 15.8 x 10-6 |

| 1700 | 927 | 9.0 x 10-6 | 16.2 x 10-6 |

Mechanical Properties

Typicals Values at 68°F (20°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

|---|---|---|---|---|---|

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 65,000 | 448 | 125,000 | 862 | 50 | 200 Brinell |

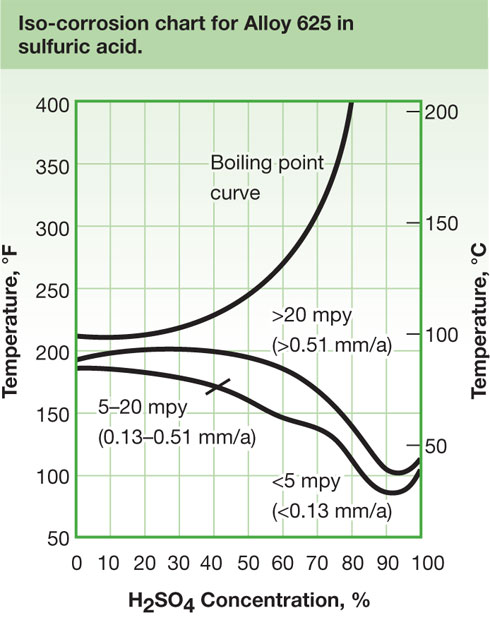

Corrosion Resistance

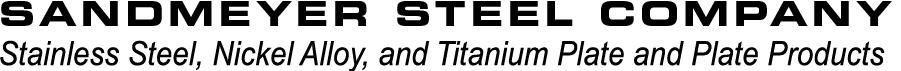

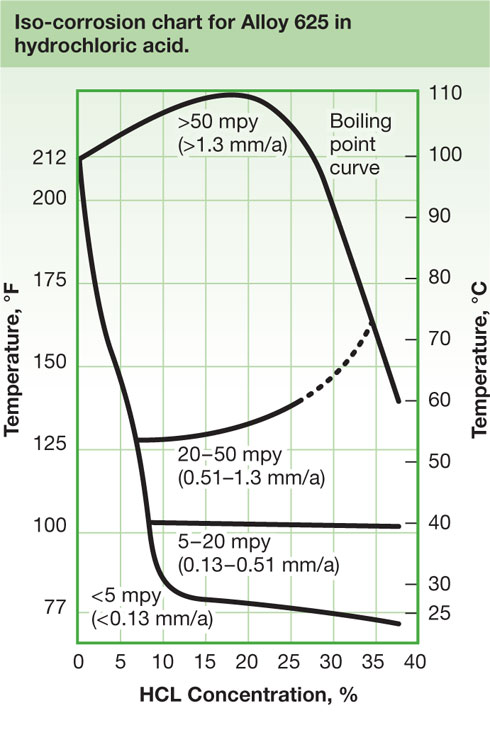

The highly alloyed chemical composition of Alloy 625 imparts outstanding corrosion resistance in a variety of severely corrosive environments. The alloy is virtually immune to attack in mild conditions such as the atmosphere, fresh and sea water, neutral salts and alkaline solutions. Nickel and chromium provide resistance to oxidizing solutions and the combination of nickel and molybdenum supply resistance in non-oxidizing environments. Molybdenum also makes Alloy 625 resistant to pitting and crevice corrosion, while niobium acts as a stabilizer during welding to prevent intergranular cracking. The high nickel content of Alloy 625 makes it virtually immune to chloride stress corrosion cracking.

The alloy resists attack by mineral acids such as hydrochloric, nitric, phosphoric and sulfuric, and to alkalis and organic acids in both oxidizing and reducing conditions.

Corrosion-resistance of nickel alloys in 24-hour tests in boiling 40% formic acid.

| Alloy | Corrosion Rate | |

|---|---|---|

| mpy | mm/a | |

| Alloy 825 | 7.9 | 0.2 |

| Nickel 200 | 10.3-10.5 | 0.26-0.27 |

| Alloy 400 | 1.5-2.7 | 0.038-0.068 |

| Alloy 600 | 10.0 | 0.25 |

| Alloy G-3 | 1.8-2.1 | 0.046-0.05 |

| Alloy 625 | 6.8-7.8 | 0.17-0.19 |

| Alloy C-276 | 2.8-2.9 | 0.07-0.074 |

Corrosion-resistance of nickel alloys in four 24-hour tests in boiling acetic acid

| Alloy | Acetic Acid Concentration |

Corrosion/Erosion Rate | |

|---|---|---|---|

| mpy | mm/a | ||

| Alloy 825 | 10% | 0.60-0.63 | 0.0152-0.160 |

| Alloy 625 | 10% | 0.39-0.77 | 0.01-0.19 |

| Alloy C-276 | 10% | 0.41-0.45 | 0.011-0.0114 |

| Alloy 686 | 80% | <0.1* | <0.01* |

Resistance of nickel alloys to impingement attack by seawater at 150 ft/sec (45.7 m/s)

| Alloy | Corrosion/Erosion Rate | |

|---|---|---|

| mpy | mm/a | |

| Alloy 625 | Nil | Nil |

| Alloy 825 | 0.3 | 0.008 |

| Alloy K-500 | 0.04 | 0.01 |

| Alloy 400 | 1.5-2.7 | 0.038-0.068 |

| Alloy 600 | 0.4 | 0.01 |

| Nickel 200 | 40 | 1.0 |

The comparative PREN number for alloy 625 is shown in the table below.

Pitting resistance equivalency numbers (PREN) for corrosion resistant alloys

| Alloy | Ni | Cr | Mo | W | Nb | N | PREN |

|---|---|---|---|---|---|---|---|

| 316 Stainless Steel | 12 | 17 | 2.2 | — | — | — | 20.4 |

| 317 Stainless Steel | 13 | 18 | 3.8 | — | — | — | 23.7 |

| Alloy 825 | 42 | 21.5 | 3 | — | — | — | 26.0 |

| Alloy 864 | 34 | 21 | 4.3 | — | — | — | 27.4 |

| Alloy G-3 | 44 | 22 | 7 | — | — | — | 32.5 |

| Alloy 625 | 62 | 22 | 9 | — | 3.5 | — | 40.8 |

| Alloy C-276 | 58 | 16 | 16 | 3.5 | — | — | 45.2 |

| Alloy 622 | 60 | 20.5 | 14 | 3.5 | — | — | 46.8 |

| SSC-6MO | 24 | 21 | 6.2 | — | — | 0.22 | 48.0 |

| Alloy 686 | 58 | 20.5 | 16.3 | 3.5 | — | — | 50.8 |

Oxidation Resistance

The oxidation and scaling resistance of Alloy 625 is superior to a number of heat resistant austenitic stainless steels such as 304, 309, 310 and 347 up to 1800°F (982°C) and under cyclic heating and cooling conditions. Above 1800°F (982°C), scaling can become a restrictive factor in service.

Fabrication Data

Alloy 625 can be easily welded and processed by standard shop fabrication practices, however because the high strength of the alloy, it resists deformation at hot-working temperatures.

Hot Forming

The hot-working temperature range for Alloy 625 is 1650 – 2150°F (900 – 1177°C). Heavy working needs to occur as close to 2150°F (1177°C) as possible, while lighter working can take place down to 1700°F (927°C). Hot-working should occur in uniform reductions to prevent duplex grain structure

Cold Forming

Alloy 625 can be cold-formed by the standard shop fabrication practices. The alloy should be in the annealed condition. Work hardening rates are higher than the austenitic stainless steels.

Welding

Alloy 625 can be readily welded by most standard processes including GTAW (TIG), PLASMA, GMAW (MIG/MAG), SAW and SMAW (MMA). A post weld heat treatment is not necessary. Brushing with a stainless steel wire brush after welding will remove the heat tint and produce a surface area that does not require additional pickling.

Machining

Alloy 625 should preferably be machined in the annealed condition. Since Alloy 625 is prone to work–hardening, only low cutting speeds should be used and the cutting tool should be engaged at all times. Adequate cut depth is necessary to assure avoiding contact with the previously formed work-hardened zone.

NOTE: The information and data in this product data sheet are accurate to the best of our knowledge and belief, but are intended for informational purposes only, and may be revised at any time without notice. Applications suggested for the materials are described only to help readers make their own evaluations and decisions, and are neither guarantees nor to be construed as express or implied warranties of suitability for these or other applications.