Placa de Aleación de Níquel

La Aleación 276 (UNS N10276) es una aleación de níquel – molibdeno – cromo – hierro – tungsteno que se encuentra entre las aleaciones más resistentes a la corrosión que están disponibles actualmente. Su alto contenido de molibdeno le imparte resistencia a la corrosión localizada como las picaduras. Su bajo nivel de carbono minimiza la precipitación de carburos durante el proceso de soldadura para mantener la resistencia al ataque intergranular en las zonas afectadas por el calor de las uniones soldadas.

La Aleación 276 también tiene una buena resistencia a altas temperaturas y resistencia moderada a la oxidación, aunque eventualmente forma precipitados a altas temperaturas que la hacen quebradiza.

| 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | ||

|---|---|---|---|---|---|---|---|

| 4.8mm | 6.3mm | 9.5mm | 12.7mm | 15.9mm | 19mm | ||

| 1" | 1 1/4" | 1 1/2" | 1 3/4" | 2" | 2 1/2" | ||

| 25.4mm | 31.8mm | 38.1mm | 44.5mm | 50.8mm | 63.5mm | ||

Alloy C276 nickel alloy plate (UNS N10276) is a nickel-molybdenum-chromium-iron-tungsten alloy which is among the most corrosion-resistant alloys currently available. The high molybdenum content imparts resistance to localized corrosion such as pitting. The low carbon minimizes carbide precipitation during welding to maintain resistance to intergranular attack in heat affected zones of welding joints.

Alloy C276 nickel alloy plate also has good high temperature strength and moderate oxidation resistance although the alloy will eventually form embrittling high temperature precipitates.

Specification Sheet Overview

for Alloy C276 (UNS N10276)

W. Nr. 2.4819:

A Nickel-Molybdenum-Chromium Alloy with Excellent Corrosion Resistance in both Oxidizing and Reducing Environments

General Properties

Alloy C276 nickel alloy plate (UNS N10276) is an austenitic nickel-molybdenum-chromium alloy with a small addition of tungsten. It is one of the premier corrosion resistant materials available for process industries. Alloy C276 nickel alloy plate has excellent corrosion resistance in both oxidizing and reducing environments.

The combination of the high molybdenum and chromium content, along with the addition of tungsten, make Alloy C276 nickel alloy plate highly resistant to chloride stress corrosion cracking, pitting, crevice corrosion and general corrosion.

Alloy C276 nickel alloy plate can operate in oxidizing atmospheres up to 1900oF (1038oC), however, the alloy lacks sufficient chromium content to operate successfully in the most strongly oxidizing environments like hot, concentrated nitric acid.

The low carbon content of Alloy C276 nickel alloy plate enables the alloy to be utilized in the as-welded condition. It cannot be hardened by heat treatment, but can be hardened by cold working. The alloy has a higher work-hardening rate than the austenitic stainless steels which should be taken into consideration.

Alloy C276 nickel alloy plate can be easily welded and processed utilizing standard shop fabrication practices for austenitic stainless steels and nickel based alloys.

Applications

- Air Pollution Control – flue gas desulfurization systems – stack liners, absorbers, ducts, dampers, stack gas re-heaters and fans

- Chemical Processing – heat exchangers, pressure vessels, tanks, evaporators, piping, flanges and fittings, pumps and valves

- Oil and Gas Production – sour gas service components

- Pharmaceutical Production – reactor vessels, piping, flanges and fittings, pumps and valves

- Pulp and Paper – bleaching vessels and digesters

- Waste Treatment – incinerators for toxic, industrial and municipal waste

- Ore Processing

Standards

ASTM..................B 4575ASME..................SB 575

Chemical Analysis

Weight % (all values are maximum unless a range is otherwise indicated)

| Nickel | Balance | Manganese | 1.0 |

| Molybdenum | 15.0 min.-17.0 max. | Carbon | 0.01 |

| Chromium | 14.5 min.-16.5 max. | Vanadium | 0.35 |

| Iron | 4.0 min.-7.0 max. | Phosphorous | 0.04 |

| Tungsten | 3.0 min.-4.5 max. | Sulfur | 0.03 |

| Cobalt | 2.5 | Silicon | 0.08 |

Physical Properties

Density

0.321 lbs/in38.89 g/cm3

Specific Heat

0.102 BTU/lb-°F (70°F)427 J/kg-°K (20°C)

Modulus of Elasticity

29.8 x 106 psi205.0 GPa

Thermal Conductivity 212°F (100°C)

67 BTU/hr/ft2/ft/°F9.8 W/m-°K

Melting Range

2415 – 2500°F1325 – 1370°C

Electrical Resistivity

51 Microhm-in at 75°C1.30 Microhm-cm at 24°C

| Mean Coefficient of Thermal Expansion Temperature Range |

|||

|---|---|---|---|

| °F | °C | in/in/°F | cm/cm°C |

| 200 | 93 | 6.8 x 10-6 | 12.24 x 10-6 |

| 400 | 204 | 7.0 x 10-6 | 12.60 x 10-6 |

| 600 | 316 | 7.2 x 10-6 | 12.96 x 10-6 |

| 800 | 427 | 7.4 x 10-6 | 13.32 x 10-6 |

| 1000 | 538 | 7.8 x 10-6 | 14.0 x 10-6 |

| 1200 | 649 | 8.2 x 10-6 | 14.8 x 10-6 |

| 1400 | 760 | 8.5 x 10-6 | 15.3 x 10-6 |

| 1600 | 871 | 8.8 x 10-6 | 15.8 x 10-6 |

| 1700 | 927 | 9.0 x 10-6 | 16.2 x 10-6 |

Mechanical Properties

Typicals Values at 68°F (20°C)

| Yield Strength 0.2% Offset |

Ultimate Tensile Strength |

Elongation in 2 in. |

Hardness | ||

|---|---|---|---|---|---|

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 41,000 | 283 | 100,000 | 690 | 40 | 100 Rockwell B |

Corrosion Resistance

Alloy C276 nickel alloy plate is one of the premier corrosion resistant materials that performs exceptionally well in both oxidizing and reducing environments. It resists chloride stress corrosion cracking, pitting, crevice and general corrosion. The alloy is also resistant to carbide precipitation during welding enabling it to be utilized in the as-welded condition.

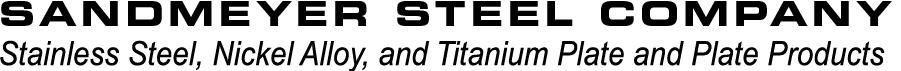

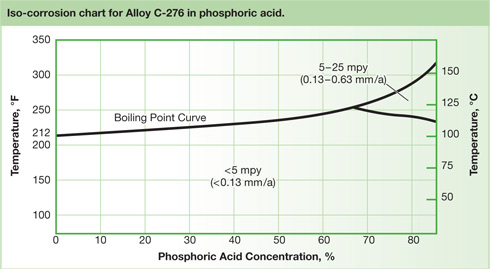

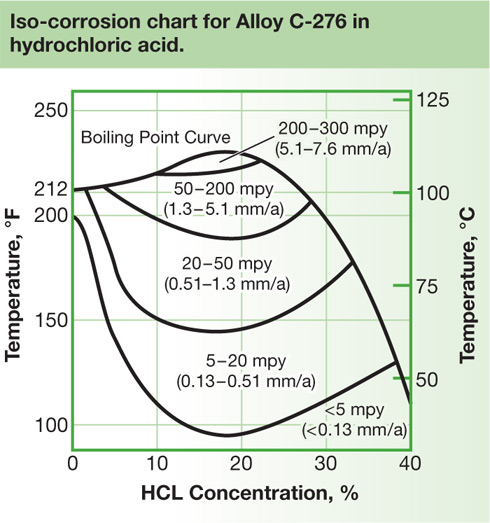

In chemical processing applications, the alloy has exceptional resistance to sulfuric, hydrochloric, formic, acetic and phosphoric acids. Alloy C276 nickel alloy plate performs well in environments containing acid chlorides, solvents and acetic anhydride, The alloy is one of the few grades that withstands wet chlorine gas, hypochlorite and chlorine dioxide solutions.

Alloy C276 nickel alloy plate is highly resistant to concentrated solutions of oxidizing salts including iron and copper chloride. It also performs well in seawater, especially under crevice conditions where other frequently used alloys such as stainless steel, Alloy 400 and Alloy 625 fail.

The operating conditions of flue gas desulfurization systems offer a challenging environment for corrosion resistant materials. Scrubber liquors and gas condensates often contain chlorides. Alloy C276 nickel alloy plate nickel alloy plate has been shown to withstand higher chloride levels than other grades before the onset of localized corrosion in these systems.

Alloy C276 nickel alloy plate is used extensively in the recovery and processing of sour natural gas which contains hydrogen sulfide along with carbon dioxide and chlorides. Carbon and alloy steels cannot withstand this corrosive environment. They are subject to failure by sulfide stress cracking or stress corrosion cracking. The rich chemistry of Alloy C276 nickel alloy plate makes it resistant to sour environments even at high temperatures in deep wells.

Corrosion Tests* in Hydrogen Fluoride Gas.

Test Duration, 36 Hours. Temperature 932-1112°F (500-600°C)

| MATERIAL | Corrosion Rate, mpy (mm/a) | Comments |

|---|---|---|

| Alloy C-276 | 0.3 (0.01) | Iridescent tarnish film |

| Alloy 600 | 0.7 (0.02) | Iridescent tarnish film |

| Nickel 200 | 9 (0.23) | Black film |

| Nickel 201 | 14 (0.36) | Black film |

| Alloy 400 | 13 (0.33) | Adherent dark film |

| Alloy K-500 | 16 (0.41) | Adherent dark film |

| 70/30 Copper-Nickel | 16 (0.41) | Adherent dark film |

* 7 lb HF per hour at 4 psig was passed through a laboratory furnace for hydroflourination of metal oxides

Corrosion-resistance of nickel alloys in four 24-hour tests in boiling acetic acid

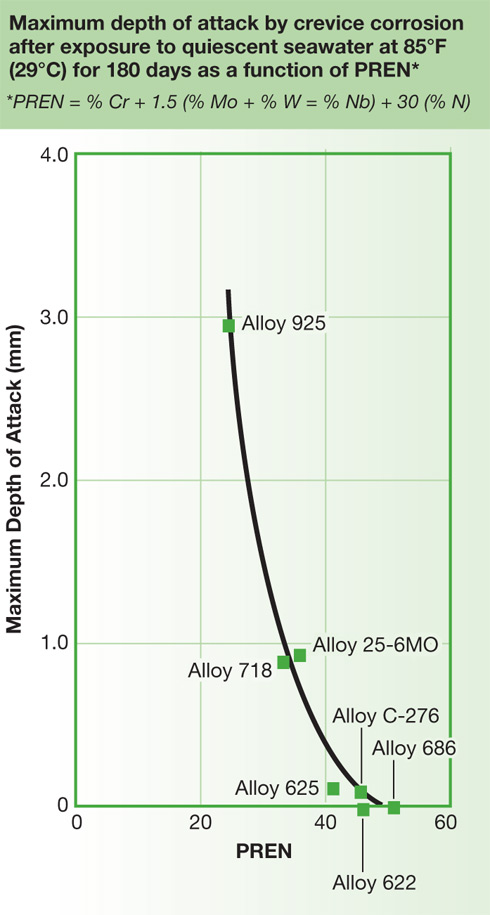

| Alloy | Ni | Cr | Mo | W | Nb | N | PREN |

|---|---|---|---|---|---|---|---|

| 316 Stainless Steel | 12 | 17 | 2.2 | — | — | — | 20.4 |

| 317 Stainless Steel | 13 | 18 | 3.8 | — | — | — | 23.7 |

| Alloy 825 | 42 | 21.5 | 3 | — | — | — | 26.0 |

| Alloy G-3 | 44 | 22 | 7 | — | — | — | 32.5 |

| Alloy 25-6MO | 25 | 20 | 6.5 | — | — | 0.20 | 35.8 |

| Alloy 625 | 62 | 22 | 9 | — | 3.5 | — | 40.8 |

| Alloy C-276 | 58 | 16 | 16 | 3.5 | — | — | 45.2 |

| Alloy 622 | 60 | 20.5 | 14 | 3.5 | — | — | 46.8 |

| Alloy 686 | 58 | 20.5 | 16.3 | 3.5 | — | — | 50.8 |

* (Pren) = %CR + 1.5 (%Mo + %W + %Nb) + 30 (%N)

Maximum Pitting or Crevice Attack, mils (MM), in FGD Scrubber Slurrya

| Alloy | Quencher | Absorber | Absorber Outlet |

Outlet Duct |

Bypass Duct |

|---|---|---|---|---|---|

| 316L Stainless Steel | 22 (0.56) | 21 (0.53) | 35 (0.89)b | 35 (0.89)b | 12 (0.30) |

| 317LM Stainless Steel | 20 (0.51) | 22 (0.56) | 29 (0.74) | 33 (0.84) | 29 (0.74) |

| Alloy 825 | 15 (0.38) | 33 (0.84) | 39 (0.99) | 50 (1.27)b | 10 (0.25) |

| Alloy 625 | <2 (<0.05) | 10 (0.25) | 11 (0.28) | 7 (0.18) | nil |

| Alloy C-276 | nil | nil | <2 (<0.05) | nil | nil |

a 6-month exposure at 126°F (62°C), pH 5.5, 5000 ppm chlorides

b Perforated.

Fabrication Data

Alloy C276 nickel alloy plate can be easily welded and processed utilizing standard shop fabrication practices for austenitic stainless steels and nickel based alloys.

Hot Forming

The hot-working temperature range for Alloy C276 nickel alloy plate is 1600 – 2250°F (870 – 1230°C). The alloy should be water quenched after hot working. Heat treatment is recommended after hot working to ensure maximum corrosion resistance.

Cold Forming

Alloy C276 nickel alloy plate should be in the annealed condition for cold working. The alloy has a higher work-hardening rate than the austenitic stainless steels which should be taken into consideration. An in-process anneal may be necessary with a high degree of cold working. If the alloy undergoes greater than 15% deformation during cold working, a solution anneal may be necessary.

Welding

Alloy C276 nickel alloy plate can be readily welded by most standard processes including GTAW (TIG), PLASMA, GMAW (MIG/MAG) and SMAW (MMA). A post weld heat treatment is not necessary. Brushing with a stainless steel wire brush after welding will remove the heat tint and produce a surface area that does not require additional pickling.

Machining

Alloy C276 nickel alloy plate should preferably be machined in the annealed condition. Since Alloy C276 nickel alloy plate is prone to work–hardening, only low cutting speeds should be used and the cutting tool should be engaged at all times. Adequate cut depth is necessary to assure avoiding contact with the previously formed work-hardened zone.

NOTE: The information and data in this product data sheet are accurate to the best of our knowledge and belief, but are intended for informational purposes only, and may be revised at any time without notice. Applications suggested for the materials are described only to help readers make their own evaluations and decisions, and are neither guarantees nor to be construed as express or implied warranties of suitability for these or other applications.